Is it possible to recover polymer waste generated during ceramic production?

This is the main question that CiPoCer project seeks to address by investigating, developing, and validating processes for the valorization of polymer waste generated during ceramic manufacturing — specifically polyurethane (PU) and poly(methyl methacrylate) (PMMA).

What is CiPoCer?

The main objective of this project is to develop recovery processes for polymer waste arising from ceramic production, namely polyurethane (PU) and poly(methyl methacrylate) (PMMA).

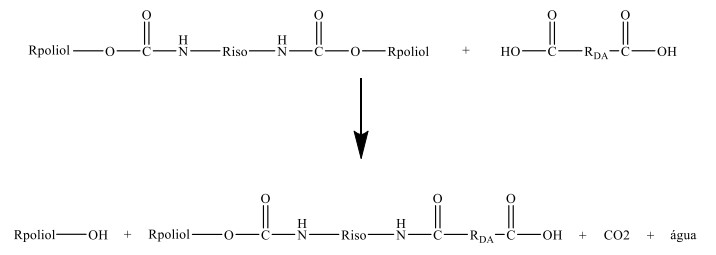

In the first case, PU waste will undergo chemical recycling through a process known as acidolysis. The reaction conditions will be optimized so that the recycled polyols obtained are of sufficient quality to be reintegrated into the production of new products, allowing for up to 30% replacement of the polyol used.

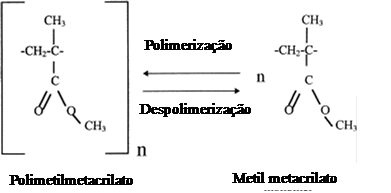

In the second case, PMMA waste will also be chemically recycled through pyrolysis. The operating conditions will be optimized for a continuous and autothermal regime, aiming to produce recycled monomers — methyl methacrylate (MMA) — with high potential for reuse in the polymerization of new recycled PMMA products. The process also generates excess thermal energy, and its integration into CV’s production process will be evaluated.

Polymers under investigation

Polyurethane

PU is a highly versatile type of polymer, used in various forms and applications such as elastomers, adhesives, coatings, and foams. Polyurethanes (PU) are synthesized through the reaction between the OH groups of a polyol and the NCO groups of an isocyanate. Due to the wide range of applications, their production has increased over the past decades, with the majority being used in the form of foam.

Poly(methylmethacrylate)

PMMA is a polymer with remarkable optical properties, good electrical insulation capacity, and high resistance to corrosion, making it widely used in industrial production and architectural decoration. The growing demand for PMMA has led to an increase in the production of this type of waste. However, since PMMA waste is not biodegradable, its final destination is typically landfill disposal or incineration.

Main Challenges

Recycling of PU waste through acidolysis, where the recovered polyols are used to produce new PU cushions, thus promoting sustainability by reducing dependence on virgin raw materials.

Valorization of PMMA waste through pyrolysis, where the resulting products are reintroduced into the production chain and the energy generated is integrated into the company’s manufacturing process.

What is the environmental impact of these polymers?

Polymer production has increased substantially over the past 60 years, rising from around 0.5 million tonnes in 1950 to over 400 million tonnes in 2023.

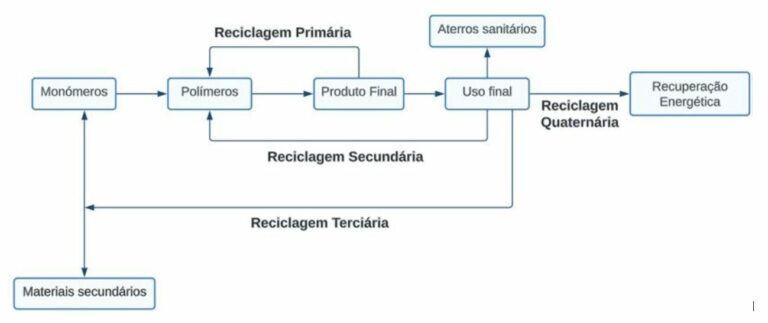

A large portion of these materials is produced from fossil resources and is not easily recyclable (SEE), which often leads to their disposal in landfills or incineration. In recent decades, growing global concern over the depletion of fossil fuels and the environmental impact of polymers has driven more sustainable approaches in the development of polymeric materials. This interest is driven by the need for a more sustainable economy and reduced dependence on fossil fuels. Public awareness of this issue has further encouraged efforts to address polymer waste. As such, reducing waste generation and developing recycling methods has become a major challenge for building a modern and environmentally friendly circular economy.

Currently, recycling is one of the most promising options in the polymer industry, as it helps to mitigate long-term environmental consequences by reducing the use of petroleum-based raw materials, cutting carbon dioxide emissions, and decreasing the amount of waste requiring disposal.

Project Goals

Ceramic bodies’ R&D with suitable compositions for firing, by using FLASH technology

R&D of FLASH sintering kilns, namely with the construction of a laboratory test’s kiln and its scale-up, into a second (pilot) kiln for porcelain’s firing

Studies for the applicability and industrial feasibility of porcelain’s FLASH sintering process

Studies for the applicability and industrial feasibility of porcelain’s FLASH sintering process

Project Expectations

- Increase of the Process’ Environmental Sustainability

- Significant Reduction on Production Costs

- Increased Competitiveness of the Companies in the Sector